Plumbers are crucial experts in installing gas lines for stoves and heating systems, ensuring safety, efficiency, and adherence to regulations. They assess sites, plan routes, and use specialized tools like pipe cutters, thread tape, and pressure gauges to connect appliances to main lines securely. Challenges include navigating tight spaces and adhering to standards; plumbers overcome these with creative routing and advanced equipment. Safety is paramount, requiring compliance with building codes, correct materials, and protective gear for handling gas.

Need help installing gas lines for your stove or heating system? This comprehensive guide, written from a plumber’s perspective, will walk you through the process step-by-step. From understanding the basics of gas line installation to common challenges and safety measures, this article equips homeowners with valuable knowledge. Learn which tools and equipment are essential, discover best practices, and gain insights into troubleshooting potential issues. Trust a professional plumber to ensure your gas line installation is safe and secure.

- Understanding Gas Line Installation: A Plumber's Perspective

- Tools and Equipment Required for the Job

- Step-by-Step Guide to Installing Gas Lines

- Common Challenges and How a Plumber Addresses Them

- Safety Measures and Best Practices for Gas Line Installation

Understanding Gas Line Installation: A Plumber's Perspective

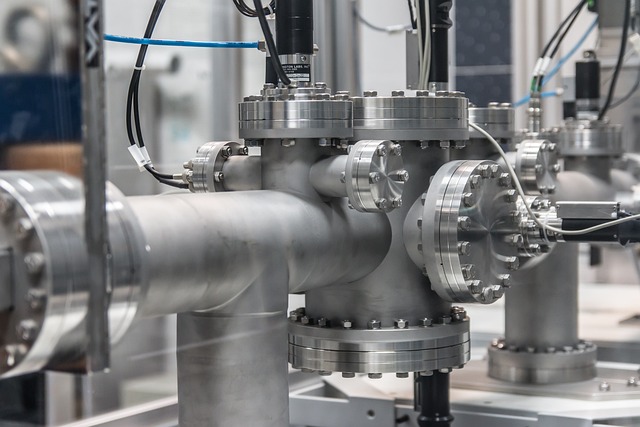

Installing gas lines for stoves or heating systems requires a meticulous approach, and plumbers play a pivotal role in this process. From assessing the site to ensuring safety and compliance with regulations, plumbers have extensive knowledge about gas line installation. They understand the intricacies of working with different types of pipes, fittings, and valves, ensuring a secure and efficient gas supply.

A plumber’s perspective involves considering factors like pipe sizing, route planning, and potential hazards. They use specialized tools and techniques to connect appliances to the main gas line, guaranteeing both functionality and safety. By adhering to industry standards and best practices, plumbers guarantee that gas lines are installed correctly, mitigating risks associated with gas leaks or improper connections.

Tools and Equipment Required for the Job

To ensure a successful installation of gas lines, several essential tools and equipment are required. A plumber, skilled in this area, should have access to a comprehensive set of utilities tailored for such tasks. This includes specialized pipe cutters capable of handling various material thicknesses, as well as thread tape and couplings specifically designed for gas lines. Additionally, a substantial pair of gloves, safety glasses, and a respirator mask are paramount to protect against hazardous fumes during the process.

Amongst other critical tools, a pressure gauge and torch kit play pivotal roles in testing and joining lines accurately. A plumber also needs a range of wrenches and adapters for securing fittings tightly. Moreover, a robust measurement tape is indispensable for precise cutting and fitting, while fire safety equipment serves as a crucial backup measure for any unforeseen incidents.

Step-by-Step Guide to Installing Gas Lines

Installing gas lines for stoves or heating systems requires careful planning and precise execution. Here’s a step-by-step guide to ensure the process is smooth and safe.

1. Assess the Space and Plan the Route: Start by examining the area where you’ll be installing the gas line. Identify the optimal route for the pipeline, considering factors like existing structures, appliances, and accessibility. This planning phase is crucial for minimizing disruptions and ensuring the safety of your home or property. Consult with a professional plumber to determine the best approach.

2. Gather Necessary Tools and Materials: Based on your assessment, create a list of required tools and materials, including pipes, fittings, connectors, and any specialized equipment. Ensure all items are compatible with gas lines and meet local safety standards. A plumber can advise on specific products and help you source them from reputable suppliers.

3. Mark the Gas Line Route: Using a durable marker, clearly outline the path of the gas line on the floor or walls to guide your installation. This step prevents accidental damage during the process.

4. Prepare the Pipeline: Cut and shape the pipes to fit the planned route using specialized tools. Ensure all edges are smooth to prevent leaks. Connect the pipes with fittings, following manufacturer guidelines for proper assembly.

5. Install the Gas Line: Begin laying the pipeline according to your marked route. Secure pipes in place using brackets or other suitable fasteners. Maintain a consistent slope to facilitate drainage and prevent water accumulation.

6. Test for Leaks: Once the gas line is fully installed, use a leak detection solution to identify any potential breaches. This step is vital for ensuring the safety of your space and preventing hazardous situations.

Common Challenges and How a Plumber Addresses Them

When it comes to installing gas lines for stoves or heating systems, plumbers often face several common challenges. One of the primary issues is ensuring the safety and integrity of the gas lines, as any leak or misconnection can pose significant risks. Plumbers address this by using specialized tools and techniques for precise installations, regularly testing for leaks, and adhering to strict industry standards.

Another challenge lies in navigating tight spaces and obstacles within homes or buildings. Skilled plumbers overcome this by employing creative routing strategies, utilizing flexible piping where necessary, and employing advanced equipment to minimize disruptions. Their expertise allows them to efficiently install gas lines while ensuring the comfort and safety of homeowners, making them indispensable professionals for any gas line installation project.

Safety Measures and Best Practices for Gas Line Installation

When installing gas lines for stoves or heating systems, safety should always be the top priority. A plumber must ensure all work complies with local building codes and uses appropriate tools and materials certified for gas line connections. This includes selecting the correct size pipes, using thread sealants, and fitting valves and fittings securely to prevent leaks that could lead to explosions or asphyxiation. Regularly testing pressure and checking for any signs of damage or corrosion is also essential throughout the installation process.

Best practices dictate following precise measurements for route planning and avoiding potential hazards like sharp turns or kinks in the lines. Proper ventilation during installation ensures gas doesn’t accumulate to dangerous levels, minimizing risk to the plumber and homeowners alike. Always wear protective gear, including gloves, goggles, and a respirator mask when cutting pipes or handling gas, as these simple precautions can protect against injuries or health risks associated with toxic fumes.

When it comes to gas line installation for stoves or heating systems, a qualified plumber is an indispensable asset. By understanding the process from a professional’s perspective and adhering to safety best practices, plumbers ensure efficient and secure setups. With the right tools, a step-by-step approach, and strategies to overcome common challenges, these experts can navigate complex installations with ease. Trusting a plumber for your gas line needs guarantees a safe, reliable, and effective solution, ensuring peace of mind for years to come.