Backflow prevention devices, crucial for plumbers, safeguard water systems by blocking contaminated water flow reversals, ensuring health and safety in residential and commercial settings. Regular testing by skilled plumbers is vital for optimal performance and compliance with local regulations. Plumbers should follow a step-by-step guide to test these devices, including isolating the system, applying controlled pressure, inspecting results, and recording findings. Avoiding common mistakes like improper flushing or using incorrect equipment is essential for accurate testing.

As a plumber, ensuring water safety is paramount. This article delves into the crucial aspect of backflow prevention device testing—an essential practice for maintaining clean and safe water systems. We explore why regular inspections are vital for both safety and regulatory compliance. Learn about various backflow prevention devices, how to select the right one, and follow a step-by-step guide to conducting tests. Additionally, discover common mistakes to avoid, empowering you with the knowledge to provide reliable plumbing services.

- Understanding Backflow Prevention Devices: A Plumber's Perspective

- Importance of Regular Testing for Safety and Compliance

- Types of Backflow Prevention Devices: Which One to Choose?

- Step-by-Step Guide to Performing Backflow Tests

- Common Mistakes to Avoid During Backflow Prevention Device Testing

Understanding Backflow Prevention Devices: A Plumber's Perspective

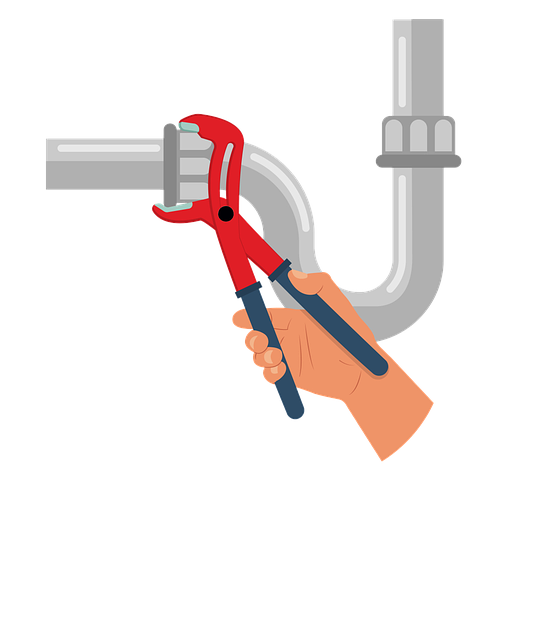

Backflow prevention devices are a crucial part of any plumbing system, designed to stop contaminated water from flowing back into the main supply. As a plumber, understanding these devices is essential for maintaining safe and efficient water systems. These mechanisms work by creating a one-way flow, ensuring that water can only move in one direction, thus preventing any backward contamination.

Plumbers often encounter various types of backflow prevention devices, each with specific applications. From residential to commercial settings, these devices are vital to prevent health hazards and ensure the integrity of the water supply. Regular testing and maintenance by skilled plumbers are necessary to guarantee their optimal performance, as it allows for early detection of any potential issues, ensuring the well-being of those relying on the plumbing system.

Importance of Regular Testing for Safety and Compliance

Regular testing of backflow prevention devices is paramount for both safety and compliance purposes, a crucial aspect often overlooked by homeowners and business owners alike. These tests ensure that the devices are functioning optimally, thereby preventing harmful contaminants from flowing back into potable water supplies. A plumber, equipped with the necessary tools and expertise, plays a vital role in this process, as they can accurately interpret test results and address any issues promptly.

Non-compliance with local regulations regarding backflow prevention can lead to severe consequences, including potential health hazards and legal penalties. Therefore, it’s essential for property owners to maintain regular testing schedules, typically recommended at least once a year. This proactive measure helps safeguard against unseen risks and ensures the integrity of water systems, promoting peace of mind for all users.

Types of Backflow Prevention Devices: Which One to Choose?

Backflow prevention devices are essential components in any plumbing system, designed to protect against hazardous backflows. These devices ensure that water flows in one direction, preventing contaminants from entering the main supply. There are several types available, each suited for different applications and levels of protection.

When choosing a backflow prevention device, consider factors like type of service (potable, irrigation, or chemical), pressure requirements, and specific regulations in your area. Common options include reduced pressure devices (RPDs) that lower pressure to prevent backflow, backflow prevention valves (BPVs) for higher pressures, and air gap fittings for simple, low-risk installations. Consulting a qualified plumber can help determine the most suitable device for your needs.

Step-by-Step Guide to Performing Backflow Tests

Performing backflow prevention device testing is a crucial task for any plumber, ensuring the safety and integrity of water supply systems. Here’s a step-by-step guide to help you navigate this process effectively.

1. Prepare Your Tools: Before beginning, gather all necessary tools including pressure gauges, test kits, and backflow devices specific to your system. Double-check that everything is in working order for accurate readings.

2. Identify the Backflow Preventer: Locate the backflow prevention device within your plumbing system. These are typically installed at service lines entering buildings, preventing contaminants from flowing back into the main water supply. Verify its type and ensure it’s suitable for the application.

3. Isolating the System: Shut off the incoming water supply to isolate the section you’re testing. This step is vital to control the flow of water during the test, ensuring safety and preventing any potential contamination.

4. Test for Backflow: Connect your pressure gauge to the outlet side of the backflow device while leaving the inlet side shut off. Apply pressure to the system (typically below 120 psi) using a pump or by opening nearby taps. Monitor the pressure gauge, checking for any unexpected increases that could indicate backflow.

5. Inspect and Record: Document the test results, noting any anomalies. Inspect the device for damage or wear; replace as needed. Record all findings for future reference and to ensure regulatory compliance.

Common Mistakes to Avoid During Backflow Prevention Device Testing

When testing backflow prevention devices, plumbers often encounter common mistakes that can lead to inaccurate results or missed issues. One of the most frequent errors is neglecting to flush the system thoroughly before testing. Backflow devices protect water supplies from contamination, so it’s vital to ensure the system is free of any existing debris or contaminants. A hasty test without a complete flush may yield false readings.

Another mistake is failing to use appropriate test equipment and procedures. Plumbers should be equipped with calibrated test meters and follow recognized testing protocols. Inaccurate measurements or deviations from standardized methods can compromise the integrity of the test results, leading to misdiagnosis and ineffective solutions. Regular training and staying updated on industry standards are key to avoiding these pitfalls during backflow prevention device testing.

As a plumber, staying abreast of backflow prevention device testing is paramount for ensuring safe and compliant water systems. Regular testing not only safeguards against hazardous backflow events but also maintains regulatory adherence. By understanding different backflow devices, their installation, and potential pitfalls, plumbers can effectively protect both residents and utilities. With the right knowledge and this comprehensive guide, professionals can confidently navigate the process, ensuring peace of mind for clients and the integrity of water supplies.